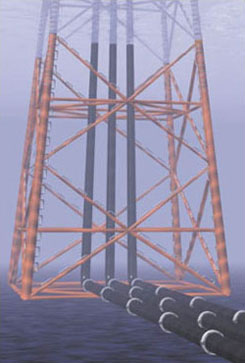

Aluminium Stand Off/Harbour Anode

Aluminium alloy anodes are now mostly preferred due to their higher electrochemical efficiency which enables them to operate at different temperature co-efficient. The anodes are less dense than zinc making them lighter and easier for handling when fitting. Systems can be designed to protect uncoated steel such as installations that have been in operation for many years. Cathodic Protection Systems shall be designed to deliver sufficient protective current to polarise the steel structure in the submerged zone and maintain that potential. For steel susceptible to hydrogen induced stress cracking (HISC), the potential value is targeted between -0.770V and -0.830 V verses the Ag/AgCl seawater reference electrode.

Zinc Stand Off/Harbour Anode

MCPS Limited Stand-off anodes are designed so that they have a minimum distance from the steel surface they are protecting of 300mm, to ensure uniform current distribution to the surface. The life period of a system is not less than five years. The anode core will support the anode to maintain the anode shape during later stages of the anode's life. Zinc material is often referred to the American Military Specification, MIL-A-18001 K. Zinc is a well-proven anode material and its capacity is virtually unaffected by the operating current density, although the driving voltage diminishes with increasing temperature therefore it has limited application.